Climate Change Research ›› 2021, Vol. 17 ›› Issue (4): 388-399.doi: 10.12006/j.issn.1673-1719.2020.287

Special Issue: 减污降碳协同增效专栏

• Pollutants and GHGs reduction synergy to enhance efficiency • Previous Articles Next Articles

Research on co-control effectiveness evaluation of energy saving and emission reduction measures in China’s iron and steel industry

GAO Yu-Bing1,2( ), XING You-Kai1,3, HE Feng1,4, KUAI Peng5, MAO Xian-Qiang1(

), XING You-Kai1,3, HE Feng1,4, KUAI Peng5, MAO Xian-Qiang1( )

)

- 1 School of Environment, Beijing Normal University, Beijing 100875, China

2 Asia-Pacific Consulting Center for Environment and Development, Beijing 100191, China

3 Transport Planning and Research Institute, Ministry of Transport, Laboratory of Transport Pollution Control and Monitoring Technology, Beijing 100028, China

4 Beijing E20 Environment Co., Ltd, Beijing 100195, China

5 School of Economics, Hefei University of Technology, Hefei 230009, China

-

Received:2020-12-08Revised:2021-02-09Online:2021-07-30Published:2021-08-11 -

Contact:MAO Xian-Qiang E-mail:zjjgyb91@mail.bnu.edu.cn;maoxq@bnu.edu.cn

Cite this article

GAO Yu-Bing, XING You-Kai, HE Feng, KUAI Peng, MAO Xian-Qiang. Research on co-control effectiveness evaluation of energy saving and emission reduction measures in China’s iron and steel industry[J]. Climate Change Research, 2021, 17(4): 388-399.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.climatechange.cn/EN/10.12006/j.issn.1673-1719.2020.287

|

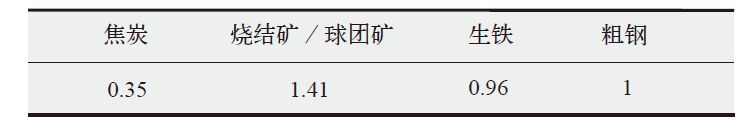

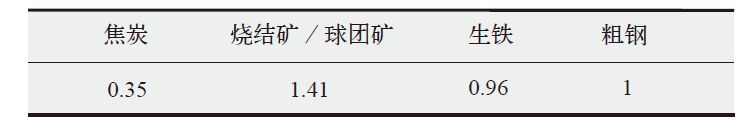

Table 3 Conversion coefficients of the volume of intermediate products and raw material corresponding to crude steel in China’s iron and steel industry

|

| [1] | 丁一汇, 李巧萍, 柳艳菊, 等. 空气污染与气候变化[J]. 气象, 2009, 35(3):3-15. |

| Ding Y H, Li Q P, Liu Y J, et al. Atmospheric aerosols, air pollution and climate change[J]. Meteorological Monthly, 2009, 35(3):3-15 (in Chinese) | |

| [2] | Nemet G F, Holloway T, Meier P. Implications of incorporating air-quality co-benefits into climate change policymaking[J]. Environmental Research Letters, 2010, 5(1):1-10 |

| [3] |

Ekins P. The secondary benefits of CO2 abatement: how much emission reduction do they justify?[J]. Ecological Economics, 1996, 16(1):13-24

doi: 10.1016/0921-8009(95)00054-2 URL |

| [4] |

Rypdal K, Rive N, Astrom S, et al. Nordic air quality co-benefits from European post-2012 climate policies[J]. Energy Policy, 2007, 35(12):6309-6322

doi: 10.1016/j.enpol.2007.07.022 URL |

| [5] |

Bell M L, Davis D L, Gouveia N, et al. The avoidable health effects of air pollution in three Latin American cities: Santiago, Sao Paulo, and Mexico city[J]. Environmental Research, 2006, 100(3):431-440

doi: 10.1016/j.envres.2005.08.002 URL |

| [6] |

Mestl H E S, Aunan K, Fang J, et al. Cleaner production as climate investment-integrated assessment in Taiyuan city, China[J]. Journal of Cleaner Production, 2005, 13(1):57-70

doi: 10.1016/j.jclepro.2003.08.005 URL |

| [7] | 李丽平, 周国梅, 季浩宇. 污染减排的协同效应评价研究: 以攀枝花市为例[J]. 中国人口∙资源与环境, 2010, 20(5):91-95. |

| Li L P, Zhou G M, Ji H Y. Study of co-benefits assessment of pollution reduction: a case study in Panzhihua[J]. China Population, Resources and Environment, 2010, 20(5):91-95 (in Chinese) | |

| [8] |

Zhou J, Mao X Q, Hu T, et al. Implications of the 11th and 12th Five-Year Plans for energy conservation and CO2 and air pollutants reduction: a case study from the city of Urumqi, China[J]. Journal of Cleaner Production, 2016, 112:1767-1777

doi: 10.1016/j.jclepro.2015.08.015 URL |

| [9] | 毛显强, 曾桉, 胡涛, 等. 技术减排措施协同控制效应评价研究[J]. 中国人口∙资源与环境, 2011 (12):1-7. |

| Mao X Q, Zeng A, Hu T, et al. Study of coordinate control effect assessment of technological measures for emissions reduction[J]. China Population, Resources and Environment, 2011 (12):1-7 (in Chinese) | |

| [10] |

West J J, Osnaya P, Laguna I, et al. Co-control of urban air pollutants and greenhouse gases in Mexico city[J]. Environmental Science & Technology, 2004, 38(13):3474-3481

doi: 10.1021/es034716g URL |

| [11] | Chae Y. Co-benefit analysis of an air quality management plan and greenhouse gas reduction strategies in the Seoul metropolitan area[J]. Environmental Science & Policy, 2010, 13(3):205-216 |

| [12] | 覃小玲. 温室气体与大气污染控制的协同减排效益研究: 以深圳市为例[D]. 广州: 华南理工大学, 2012. |

| Qin X L. Co-benefit analysis of greenhouse gas reduction and air pollution control: a case study in Shenzhen[D]. Guangzhou: South China University of Technology, 2012 (in Chinese) | |

| [13] | 中国节能协会冶金工业节能专业委员会, 冶金工业规划研究院. 中国钢铁工业节能低碳发展报告(2018)[R]. 北京, 2018. |

| Energy Saving Committee of Metallurgical Industry of China Energy Conservation Association. Energy saving and low carbon development report of China’s iron and steel industry (2018)[R]. Beijing, 2018 (in Chinese) | |

| [14] | Yang H Z, Liu J F, Jiang K J, et al. Multi-objective analysis of the co-mitigation of CO2 and PM2.5 pollution by China’s iron and steel industry[J]. Journal of Cleaner Production, 2018 (185):331-341 |

| [15] | Zhang Q, Wang Y J, Zhang W, et al. Energy and resource conservation and air pollution abatement in China’s iron and steel industry[J]. Resources, Conservation & Recycling, 2019 (147):67-84 |

| [16] | 任明, 徐向阳. 京津冀地区钢铁行业能效提升潜力和环境协同效益[J]. 工业技术经济, 2018, 37(8):20-26. |

| Ren M, Xu X Y. Energy efficiency improvement and environmental co-benefits of iron and steel industry in Beijing-Tianjin-Hebei region[J]. Journal of Industrial Technological Economics, 2018, 37(8):20-26 (in Chinese) | |

| [17] | 毛显强, 曾桉, 刘胜强, 等. 钢铁行业技术减排措施硫、氮、碳协同控制效应评价研究[J]. 环境科学学报, 2012 (5):1253-1260. |

| Mao X Q, Zeng A, Liu S Q, et al. Assessment of SO2, NOx and CO2 co-control effects by technological reduction measures in iron & steel industry[J]. Acta Scientiae Circumstantiae, 2012 (5):1253-1260 (in Chinese) | |

| [18] |

Mao X Q, Zeng A, Hu T, et al. Co-control of local air pollutants and CO2 in the Chinese iron and steel industry[J]. Environmental Science & Technology, 2013, 47(21):12002-12010

doi: 10.1021/es4021316 URL |

| [19] | 刘胜强, 毛显强, 胡涛, 等. 中国钢铁行业大气污染与温室气体协同控制路径研究[J]. 环境科学与技术, 2012 (7):168-174. |

| Liu S Q, Mao X Q, Hu T, et al. Roadmap of co-control of air pollutants and GHGs in iron and steel industry in China[J]. Environmental Science & Technology, 2012 (7):168-174 (in Chinese) | |

| [20] | Wu X C, Zhao L, Zhang Y X, et al. Cost and potential of energy conservation and collaborative pollutant reduction in the iron and steel industry in China[J]. Applied Energy, 2016 (184):171-183 |

| [21] | 马丁, 陈文颖. 中国钢铁行业技术减排的协同效益分析[J]. 中国环境科学, 2015, 35(1):298-303. |

| Ma D, Chen W Y. Analysis of the co-benefit of emission reduction measures in China’s iron and steel industry[J]. China Environmental Science, 2015, 35(1):298-303 (in Chinese) | |

| [22] | 中华人民共和国生态环境部. 中华人民共和国环境保护税法(2018年修正)[Z/OL]. 2018 [2020-05-17]. http://www.mee.gov.cn/ywgz/fgbz/fl/201811/t20181114_673632.shtml. |

| Ministry of Ecology and Environmental of the People’s Republic of China. Environmental protection law of the People’s Republic of China (2018 revision) [Z/OL]. 2018 [2020-05-17]. http://www.mee.gov.cn/ywgz/fgbz/fl/201811/t20181114_673632.shtml (in Chinese) | |

| [23] | 财政部, 国家发展改革委, 环境保护部. 挥发性有机物排污收费试点办法(财税[2015]71号) [EB/OL]. 2015 [2020-10-05]. http://zfs.mee.gov.cn/hjjj/gjfbdjjzcx/lssfzc/201509/P020150918557077581557.pdf. |

| Ministry of Finance of the People’s Republic of China, National Development and Reform Commission, Ministry of Environment of the People’s Republic of China. Pilot measures for volatile organic compound discharge fees (No.71 [2015] of Ministry of Finance of the People’s Republic of China) [EB/OL]. 2015 [2020-10-05]. http://zfs.mee.gov.cn/hjjj/gjfbdjjzcx/lssfzc/201509/P020150918557077581557.pdf (in Chinese) | |

| [24] | IPCC. Climate change 2013: the physical science basis [M]. Cambridge: Cambridge University Press, 2013 |

| [25] | 邢有凯, 毛显强, 冯相昭, 等. 城市蓝天保卫战行动协同控制局地大气污染物和温室气体效果评估: 以唐山市为例[J]. 中国环境管理, 2020, 12(4):20-28. |

| Xing Y K, Mao X Q, Feng X Z, et al. An effectiveness evaluation of co-controlling local air pollutants and GHGs by implementing blue sky defense action at city level: a case study of Tangshan city[J]. Chinese Journal of Environmental Management, 2020, 12(4):20-28 (in Chinese) | |

| [26] | 国家发展和改革委员会. 国家重点节能低碳技术推广目录(节能部分)[R]. 北京, 2015. |

| National Development and Reform Commission. National key energy-saving and low-carbon technology promotion catalog (Energy saving part)[R]. Beijing, 2015 (in Chinese) | |

| [27] | 熊华文, 符冠云. 重塑能源: 面向2050年能源消费和生产革命路线图∙中国∙工业卷 [M]. 北京: 中国科学技术出版社, 2017. |

| Xiong H W, Fu G Y. Reshaping energy: a roadmap for the energy consumption and production revolution in 2050∙China∙industry volume [M]. Beijing: China Science and Technology Press, 2017 (in Chinese) | |

| [28] | 中国钢铁工业年鉴编辑委员会. 中国钢铁工业年鉴2018 [M]. 北京: 冶金工业出版社, 2018. |

| China Iron and Steel Industry Yearbook Editorial Committee. China steel yearbook 2018 [M]. Beijing: Metallurgical Industry Press, 2018 (in Chinese) | |

| [29] | 黄导. 2016年中国钢铁工业节能环保进展情况分析[J]. 中国钢铁业, 2017 (7):12-18. |

| Huang D. Analysis of energy conservation and environmental protection in China’s steel industry in 2016[J]. China Steel, 2017 (7):12-18 (in Chinese) | |

| [30] | 段文娇, 郎建垒, 程水源, 等. 京津冀地区钢铁行业污染物排放清单及对PM2.5影响[J]. 环境科学, 2018, 39(4):1445-1454. |

| Duan W J, Lang J L, Cheng S Y, et al. Air pollutant emission inventory from iron and steel industry in the Beijing-Tianjin-Hebei region and its impact on PM2.5[J]. Environmental Science, 2018, 39(4):1445-1454 (in Chinese) | |

| [31] | 环境保护部. 纳入排污许可管理的火电等17个行业污染物实际排放量计算方法(含排污系数、物料衡算方法)(试行)[S/OL]. 2017 [2020-10-05]. http://www.mee.gov.cn/gkml/hbb/bgg/201712/t20171229_428887.htm. |

| Ministry of Environment of the People’s Republic of China. Calculation method of actual pollutant emission of 17 industries including thermal power and other industries included in pollution discharge permit management (Including pollution discharge coefficient and material balance method) (for trial implementation) [S/OL]. 2017 [2020-10-05]. http://www.mee.gov.cn/gkml/hbb/bgg/201712/t20171229_428887.htm (in Chinese) | |

| [32] | IPCC. 2006 IPCC guidelines for national greenhouse gas inventories[R/OL]. 2006 [2020-01-01]. https://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html |

| [33] | 《中国电力年鉴》编辑委员会. 中国电力年鉴2017 [M]. 北京: 中国电力出版社, 2017. |

| China Electric Power Yearbook Editorial Committee. China electric power yearbook 2017 [M]. Beijing: China Electric Power Press, 2017 (in Chinese) | |

| [34] | 人民网. 《中国电力行业年度发展报告2019》在京发布 [EB/OL]. 2019 [2020-10-05]. http://energy.people.com.cn/power/n1/2019/0614/c71901-31137585.html. |

| People Net. China power industry annual development report 2019 released in Beijing [EB/OL]. 2019 [2020-10-05]. http://energy.people.com.cn/power/n1/2019/0614/c71901-31137585.html (in Chinese) | |

| [35] | 环境保护部. 大气可吸入颗粒物一次源排放清单编制技术指南(试行)[S/OL]. 2014 [2020-10-05]. http://www.mee.gov.cn/gkml/hbb/bgg/201501/t20150107_293955.htm. |

| Ministry of Environment of the People’s Republic of China. Technical guidelines for compiling the primary source emission inventory of inhalable particulate matter (For trial implementation) [S/OL]. 2014 [2020-10-05]. http://www.mee.gov.cn/gkml/hbb/bgg/201501/t20150107_293955.htm (in Chinese) | |

| [36] | 陈德胜, 邓艳, 张扬健, 等. 我国钢铁行业2020年和2030年煤炭需求分析[J]. 煤炭经济研究, 2015, 35(8):39-42. |

| Chen D S, Deng Y, Zhang Y J, et al. Analysis on coal demands of China iron and steel industry from 2020 to 2030[J]. Coal Economic Research, 2015, 35(8):39-42 (in Chinese) | |

| [37] | 赵羚杰. 中国钢铁行业大气污染物排放清单及减排成本研究[D]. 杭州: 浙江大学, 2016. |

| Zhao L J. Study on air pollutant emission of iron and steel plants in China and the cost of emission reduction[D]. Hangzhou: Zhejiang University, 2016 (in Chinese) | |

| [38] | 李全战. 未来中长期全国钢铁行业煤炭需求预测[J]. 中国煤炭, 2015, 41(2):5-7. |

| Li Q Z. Prediction of Chinese iron and steel industry coal demand in mid-long-term in the future[J]. China Coal, 2015, 41(2):5-7 (in Chinese) | |

| [39] | 搜狐网. 全国最新电网销售电价汇总(9月1日执行)[EB/OL]. 2018 [2020-10-05]. https://www.sohu.com/a/271827080_146940. |

| Sohu Net. Summary of the latest nationwide power grid sales price (Implemented on September 1)[EB/OL]. 2018 [2020-10-05]. https://www.sohu.com/a/271827080_146940 (in Chinese) | |

| [40] | 王庆一. 2019能源数据 [R]. 北京: 绿色创新发展中心, 2019. |

| Wang Q Y. 2019 energy data[R]. Beijing: Innovative Green Development Program, 2019 (in Chinese) |

| [1] | TAN Qi-Lu, LIU Lan-Ting, ZHU Song-Li. Study on the benchmark method for national carbon trading in China’s iron and steel industry [J]. Climate Change Research, 2021, 17(5): 590-597. |

| [2] | XING You-Kai, LIU Zheng-Yan, MAO Xian-Qiang, GAO Yu-Bing, HE Feng, YU Hong. Research on co-control effect of environmental economic policies in China’s transportation sector [J]. Climate Change Research, 2021, 17(4): 379-387. |

| [3] | HE Feng, LIU Zheng-Yan, XING You-Kai, GAO Yu-Bing, MAO Xian-Qiang. Co-control effect evaluation of the energy saving and emission reduction measures in Chinese cement industry [J]. Climate Change Research, 2021, 17(4): 400-409. |

| [4] | MAO Xian-Qiang, ZENG An, XING You-Kai, GAO Yu-Bing, HE Feng. From concept to action: a review of research on co-benefits and co-control of greenhouse gases and local air pollutants reductions [J]. Climate Change Research, 2021, 17(3): 255-267. |

| [5] | FENG Xiang-Zhao, ZHAO Meng-Xue, WANG Min, DU Xiao-Lin, TIAN Chun-Xiu, GAO Ji. Simulation research on co-controlling pollutants and greenhouse gases emission in China's transportation sector [J]. Climate Change Research, 2021, 17(3): 279-288. |

| [6] | WANG Min, FENG Xiang-Zhao, DU Xiao-Lin, WU Li-Ping, ZHAO Meng-Xue, WANG Peng, AN Qi. Evaluation of co-controlling GHGs from pollutant reduction facilities in the industrial sectors, empirical analysis based on data in Chongqing city [J]. Climate Change Research, 2021, 17(3): 296-304. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||