气候变化研究进展 ›› 2025, Vol. 21 ›› Issue (5): 698-708.doi: 10.12006/j.issn.1673-1719.2025.039

中国海上风电制氢技术经济性研究

- 1

山西财经大学管理科学与工程学院 太原 030006

2山西财经大学双碳产业研究院 太原 030006

-

收稿日期:2025-02-25修回日期:2025-04-27出版日期:2025-09-30发布日期:2025-08-21 -

作者简介:徐燕,女,副教授,xwwyfy@sina.com -

基金资助:山西省哲学社会科学规划课题(2024YB085);山西省自然科学研究面上项目(202303021221183);山西财经大学双碳产业研究院2025年度项目山西省制氢产业系统演化路径及激励政策组合设计(SCST2025N10)

The economic feasibility of hydrogen production technology from offshore wind power in China

XU Yan1,2( ), PEI Jia-Mei1, ZHANG Xin-Yu1

), PEI Jia-Mei1, ZHANG Xin-Yu1

- 1

School of Management Science and Engineering ,Shanxi University of Finance and Economics Taiyuan 030006, China

2Institute of Dual Carbon Industry ,Shanxi University of Finance and Economics Taiyuan 030006, China

-

Received:2025-02-25Revised:2025-04-27Online:2025-09-30Published:2025-08-21

摘要:

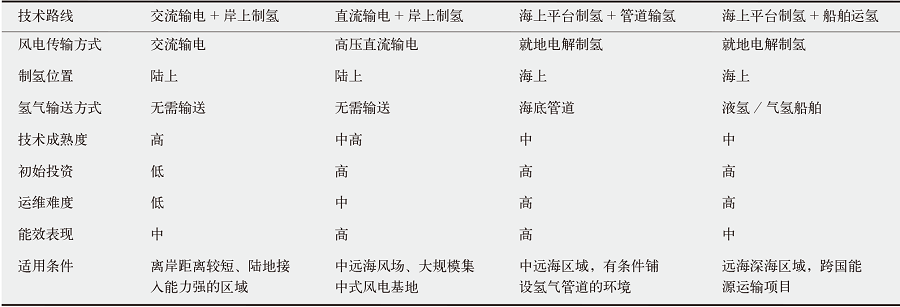

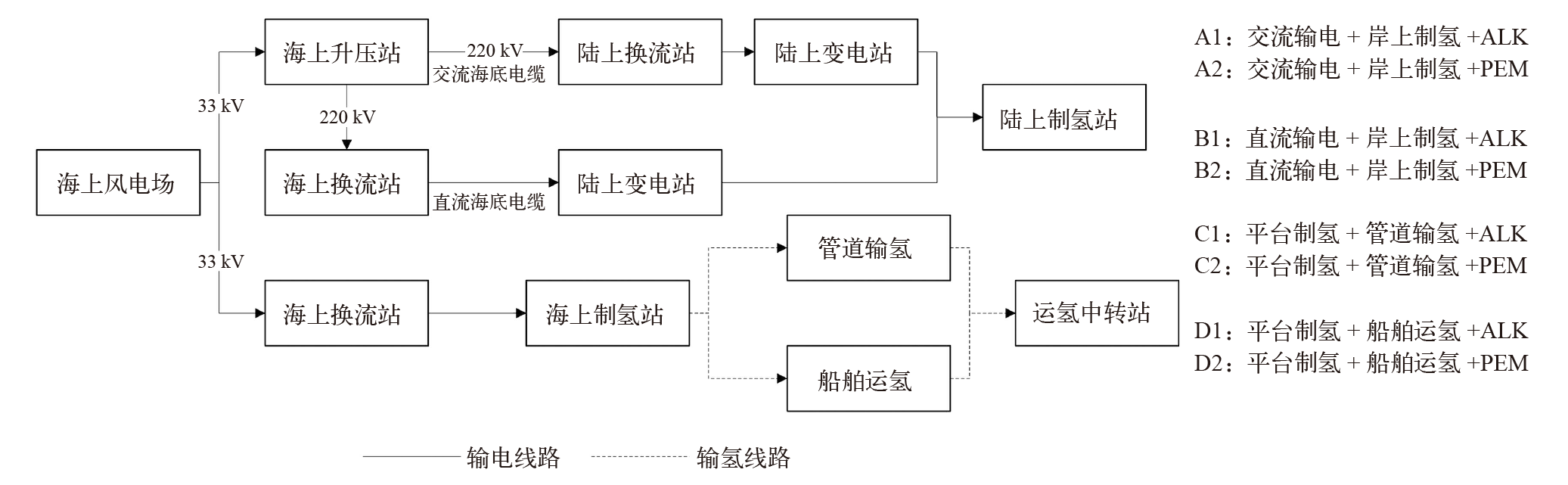

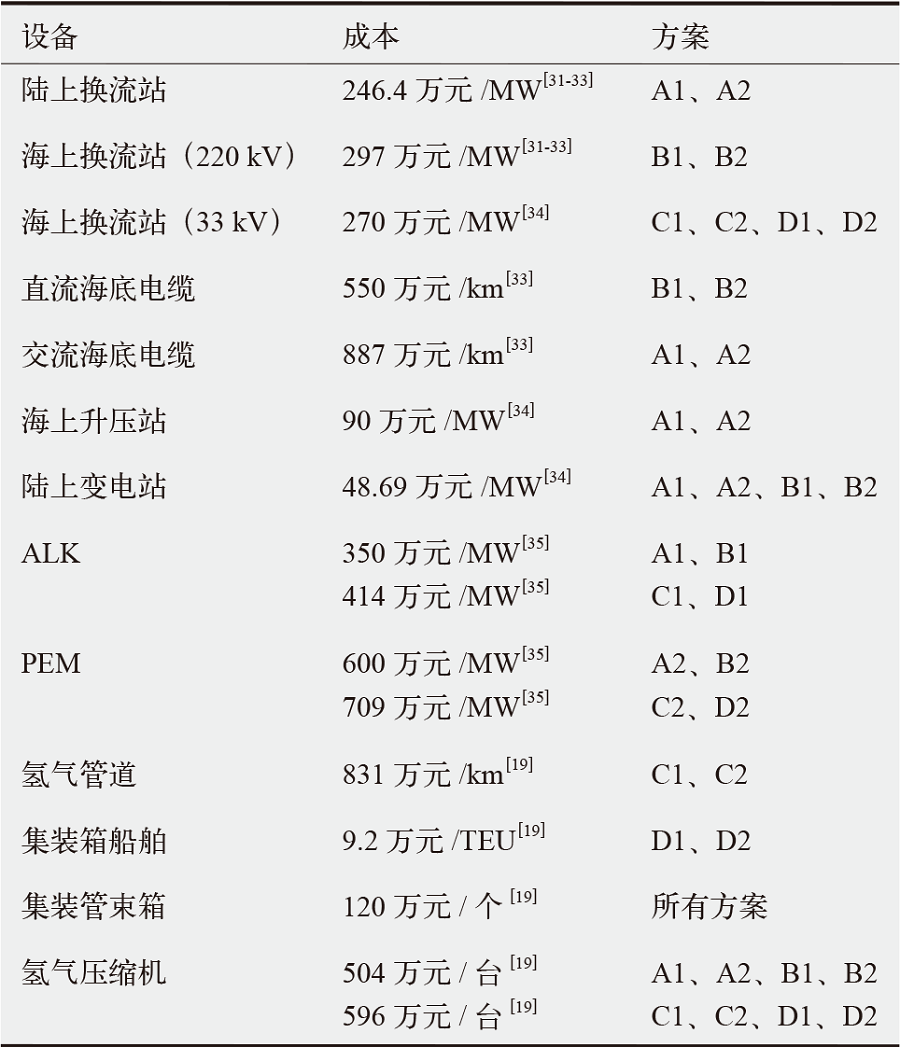

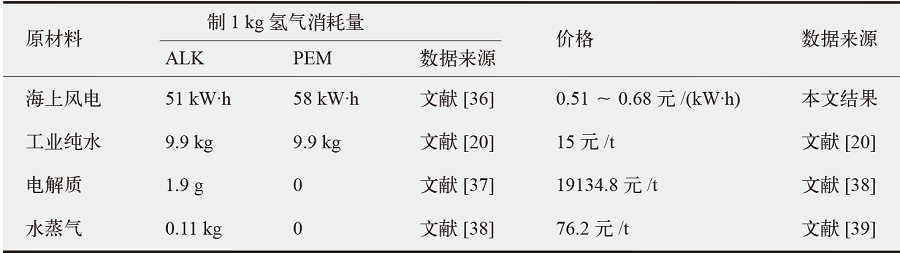

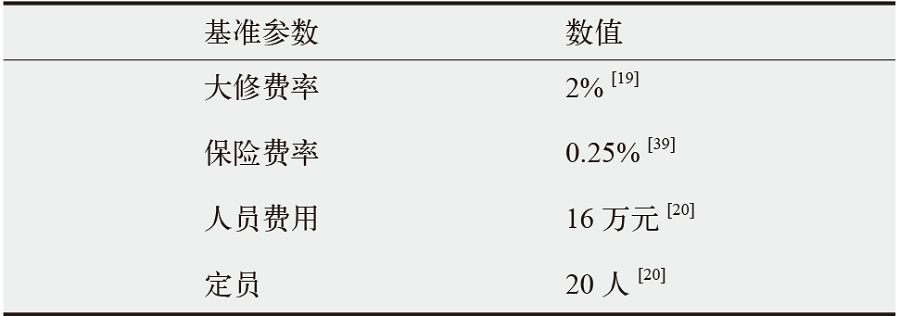

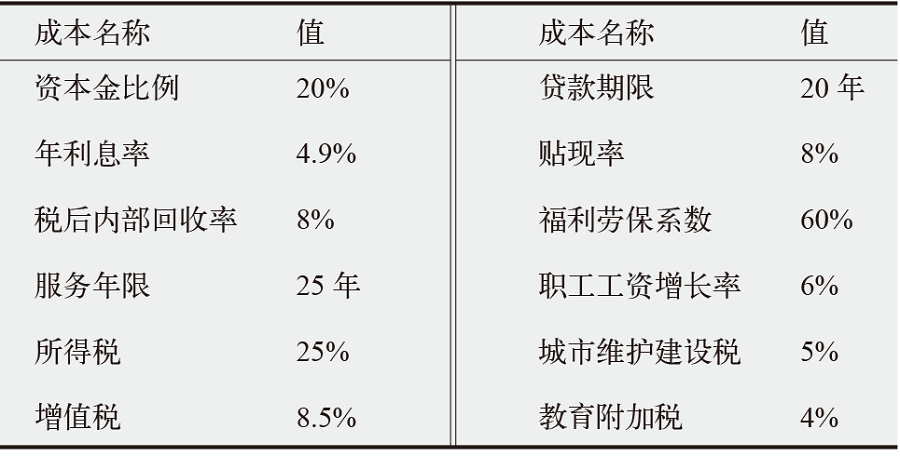

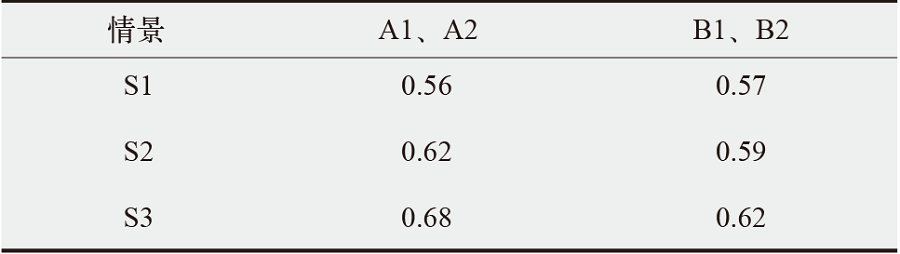

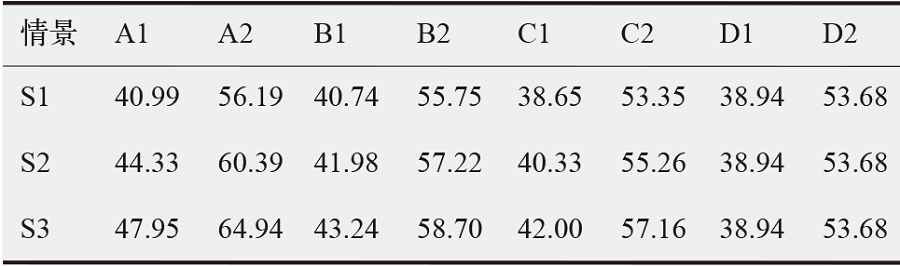

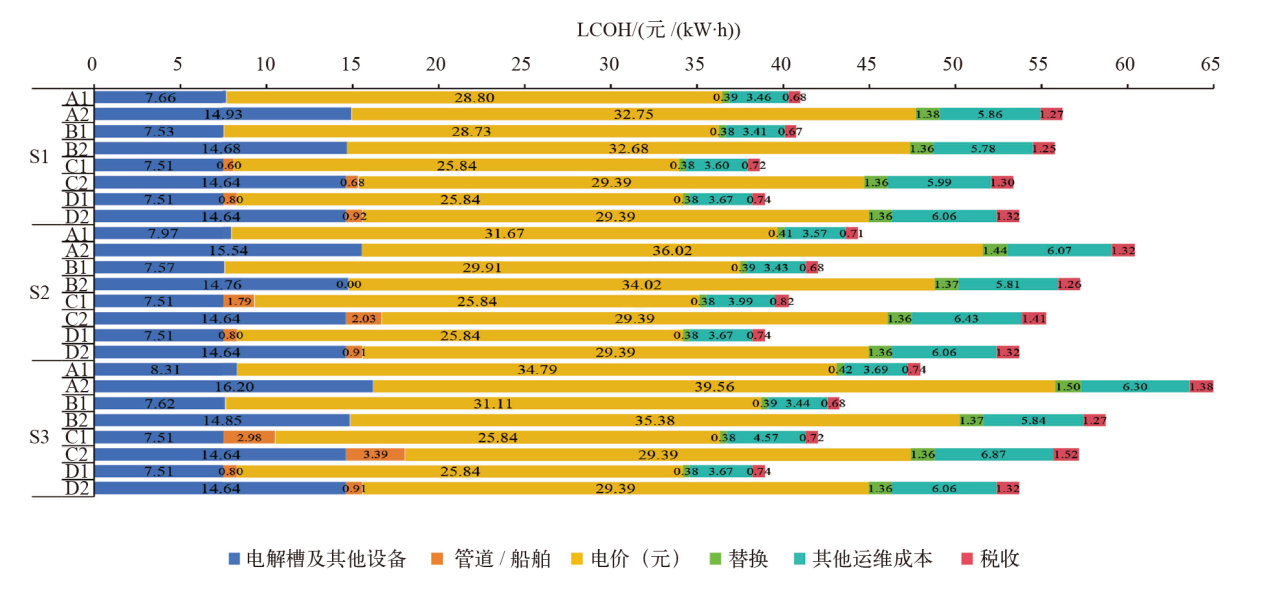

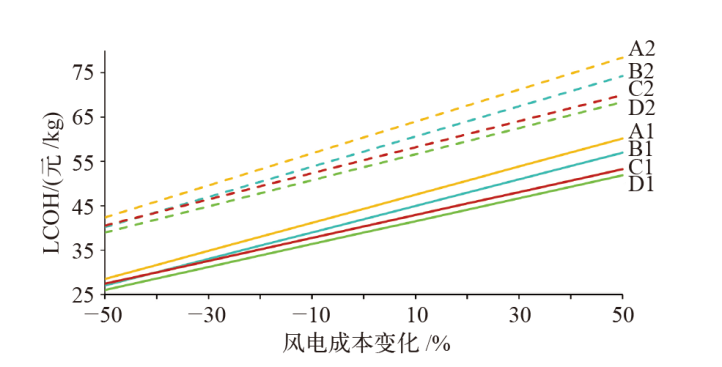

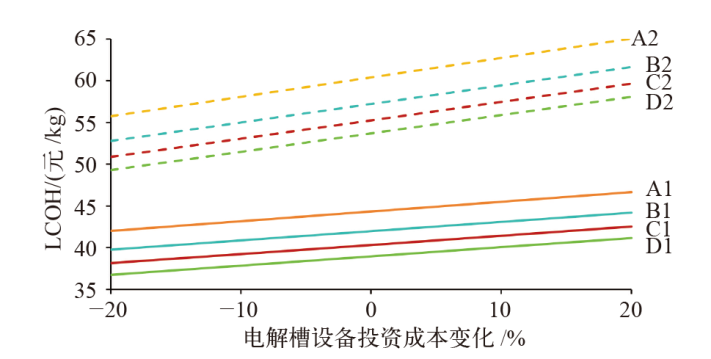

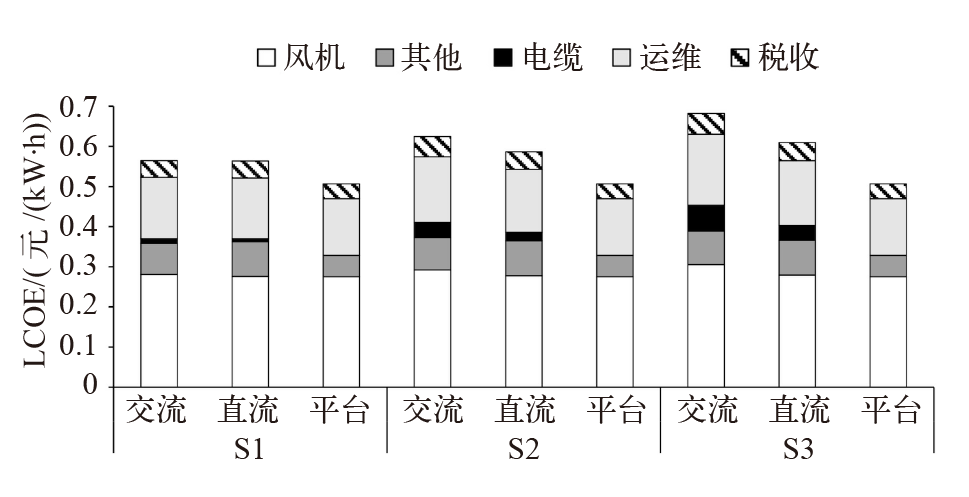

聚焦中国海上风电制氢技术的经济性评估,通过构建平准化制氢成本(LCOH)模型对海上风电交流输电岸上制氢、直流输电岸上制氢、平台制氢管道输氢以及平台制氢船舶运氢进行研究,考虑电解槽种类以及离岸距离对制氢技术经济性的影响,设置了8种技术方案,3种情景(离岸距离分别为20、60、100 km)。此外,选取风电电价和电解槽成本对制氢技术经济性进行灵敏度分析。研究表明:(1)平台制氢的经济性优于岸上制氢。当离岸距离超过20 km时,海上平台制氢结合船舶运输方案更具成本优势。(2)岸上制氢中,与交流输电相比,由于直流电缆成本低、损耗小,因此直流输电更具竞争力。(3)碱性电解槽(ALK)技术较质子交换膜(PEM)更具备显著成本竞争力,基准情景下LCOH分别为38.94~44.33元/kg和53.68~60.39元/kg。(4)电价与电解槽投资成本对LCOH的影响均呈线性特征,当电价或电解槽设备投资成本上升时制氢成本呈线性增长。(5)若采用海上风电弃电(电力价格为0),岸基制氢成本显著降低,大幅提升氢气的经济性,同时有助于改善当前海上风电消纳能力不足的现状。

引用本文

徐燕, 裴佳梅, 张欣钰. 中国海上风电制氢技术经济性研究[J]. 气候变化研究进展, 2025, 21(5): 698-708.

XU Yan, PEI Jia-Mei, ZHANG Xin-Yu. The economic feasibility of hydrogen production technology from offshore wind power in China[J]. Climate Change Research, 2025, 21(5): 698-708.

图2 不同制氢技术方案中海上风电的平准化度电成本(LCOE)构成

Fig. 2 Composition of levelized cost of electricity (LCOE) for offshore wind power in different hydrogen production technical schemes

| [1] | 吴姗姗, 王双, 彭洪兵, 等. 我国海上风电产业发展思路与对策建议[J]. 经济纵横, 2017 (1): 68-73. |

| Wu S S, Wang S, Peng H B, et al. Ideas and countermeasures for development of offshore wind power industry in our country[J]. Vertical and Horizontal of Economy, 2017 (1): 68-73 (in Chinese) | |

| [2] | Tuan A H, Ashok P, Eric L, et al. Green hydrogen economy: prospects and policies in Vietnam[J]. International Journal of Hydrogen Energy, 2023, 48 (80): 31049-31062 |

| [3] |

曾升, 李进, 王鑫, 等. 中国氢能利用技术进展及前景展望[J]. 电源技术, 2022, 46 (7): 716-722.

doi: 10.3969/j.issn.1002-087X.2022.07.005 |

| Zeng S, Li J, Wang X, et al. Progress and prospect of hydrogen energy utilization technology in China[J]. Power Supply Technology, 2022, 46 (7): 716-722 (in Chinese) | |

| [4] | International Energy Agency (IEA). The future of hydrogen[R/OL]. 2019 [2025-01-05]https://www.iea.org/reports/the-future-of-hydrogen |

| [5] | Hassan Q, Algburi S, Sameen A Z, et al. Green hydrogen: a pathway to a sustainable energy future[J]. International Journal of Hydrogen Energy, 2024, 50: 310-333 |

| [6] | 黄元生, 刘诗剑. 中国新能源制氢潜力评价研究: 基于31省份2017年和2030年的分析[J]. 生态经济, 2021, 37 (3): 74-79. |

| Huang Y S, Liu S J. Research on the potential evaluation of hydrogen production from new energy sources in China: based on the analysis of 31 provinces in 2017 and 2030[J]. Ecological Economy, 2021, 37 (3): 74-79 (in Chinese) | |

| [7] | Hussam K W, Barhoumi M E, Niby A M, et al. Techno-economic analysis and optimization of hydrogen production from renewable hybrid energy systems: Shagaya renewable power plant-Kuwait[J]. International Journal of Hydrogen Energy, 2024: 5856-5868 |

| [8] | 葛书强, 白洁, 丁永春, 等. 可再生能源制氢技术及其主要设备发展现状及展望[J]. 太原理工大学学报, 2024, 55 (5): 1-39. |

| Ge S Q, Bai J, Ding Y C, et al. Development status and prospect of renewable energy hydrogen production technology and its main equipment[J]. Journal of Taiyuan University of Technology, 2024, 55 (5): 1-39 (in Chinese) | |

| [9] | 李海鹏, 孙邦兴, 李嘉烨. 双碳目标下绿色制氢技术的进展[J]. 电池, 2024, 54 (2): 271-275. |

| Li H P, Sun B X, Li J Y. Progress of green hydrogen production technology under dual carbon targets[J]. Battery Cell, 2024, 54 (2): 271-275 (in Chinese) | |

| [10] | Abbasi R, Setzler B P, Lin S, et al. A roadmap to low-cost hydrogen with hydroxide exchange membrane electrolyzers[J]. Advanced Materials, 2019, 31 (31): e1805876 |

| [11] | 刘玮, 万燕鸣, 熊亚林, 等. 碳中和目标下电解水制氢关键技术及价格平准化分析[J]. 电工技术学报, 2022, 37 (11): 2888-2896. |

| Liu W, Wan Y M, Xiong Y L, et al. Analysis of key technologies and price leveling for hydrogen production from electrolytic water under carbon neutral target[J]. Journal of Electrotechnology, 2022, 37 (11): 2888-2896 (in Chinese) | |

| [12] | Cheng C, An R, Dong K, et al. Can the future be bright? Evolutionary game analysis of multi-stakeholders in the blue and green hydrogen development[J]. International Journal of Hydrogen Energy, 2024: 67294-67311 |

| [13] | Gonzalez-Arceo A, Blanco-Aguilera R, Berasategi J, et al. Techno-economic assessment of far-offshore hydrogen-carrying energy vectors off the Iberian Peninsula[J]. Energy Conversion & Management, 2024, 300: 117915 |

| [14] | McDonagh S, Ahmed S, Desmond C, et al. Hydrogen from offshore wind: investor perspective on the profitability of a hybrid system including for curtailment[J]. Applied Energy, 2020, 265: 114732 |

| [15] | Sovacool B K, Hirsh R F. Island wind-hydrogen energy: a significant potential US resource[J]. Renewable Energy, 2008, 33 (8): 1928-1935 |

| [16] | Dinh V N, Mckeogh E. Offshore wind energy: technology opportunities and challenges[C]. Springer Singapore:Proceedings of the 1st Vietnam Symposium on Advances in Offshore Engineering, 2019: 3-22 |

| [17] | Genc M S, Çelik M, Karasu İ. A review on wind energy and wind-hydrogen production in Turkey: a case study of hydrogen production via electrolysis system supplied by wind energy conversion system in Central Anatolian Turkey[J]. Renewable and Sustainable Energy Reviews, 2012, 16 (9): 6631-6646 |

| [18] |

张焱, 郝振波, 朱振涛, 等. 海上风能岸上制氢的经济可行性分析[J]. 电力建设, 2023, 44 (3): 148-154.

doi: 10.12204/j.issn.1000-7229.2023.03.015 |

|

Zhang Y, Hao Z B, Zhu Z T, et al. Economic feasibility analysis of onshore hydrogen production using offshore wind power[J]. Electric Power Construction, 2023, 44 (3): 148-154 (in Chinese)

doi: 10.12204/j.issn.1000-7229.2023.03.015 |

|

| [19] |

田甜, 李怡雪, 黄磊, 等. 海上风电制氢技术经济性对比分析[J]. 电力建设, 2021, 42 (12): 136-144.

doi: 10.12204/j.issn.1000-7229.2021.12.015 |

| Tian T, Li Y X, Huang L, et al. Comparative analysis of economic efficiency of hydrogen production from offshore wind power[J]. Electric Power Construction, 2021, 42 (12): 136-144 (in Chinese) | |

| [20] | 张岑, 魏华, 庄妍, 等. 海上风电制氢经济评价模型及关键影响参数[J]. 天然气工业, 2023, 43 (2): 146-154. |

| Zhang C, Wei H, Zhuang Y, et al. Economic evaluation model and key influencing parameters of hydrogen production from offshore wind power[J]. Natural Gas Industry, 2023, 43 (2): 146-154 (in Chinese) | |

| [21] | Armiño B F, Patrícia B, Costa R N, et al. Assessment of offloading pathways for wind-powered offshore hydrogen production: energy and economic analysis[J]. Applied Energy, 2021: 286 |

| [22] | Hong C, Wang Y, Estefen F S, et al. Layout optimization of the “Pipe+Ship” transmission network for the decentralized offshore wind power-hydrogen production[J]. International Journal of Hydrogen Energy, 2024: 59991-591003 |

| [23] | Antoine R, Julien V, Matthieu C D, et al. Techno-economic evaluation and resource assessment of hydrogen production through offshore wind farms: a European perspective[J]. Renewable and Sustainable Energy Reviews, 2023: 187 |

| [24] | Zhang C, Song P, Hou J, et al. Technical and economic analysis of hydrogen production, storage and transportation by offshore wind power in different scenarios: a Guangdong case study[J]. International Journal of Hydrogen Energy, 2024, 94: 829-837 |

| [25] |

Song S, Lin H, Sherman P, et al. Production of hydrogen from offshore wind in China and cost-competitive supply to Japan[J]. Nature Communications, 2021, 12 (1): 6953

doi: 10.1038/s41467-021-27214-7 pmid: 34845233 |

| [26] | Bai R, Cai G, Chen X, et al. Enriching wind power utility through offshore wind-hydrogen-chemicals nexus: feasible routes and their economic performance[J]. Journal of Cleaner Production, 2024, 476: 143732 |

| [27] | 金子儿, 王子缘, 李亚杰, 等. 我国海上风电制氢产业发展现状、问题与展望[J]. 南方能源建设, 2025, 12 (3): 33-41. |

| Jin Z E, Wang Z Y, Li Y J, et al. Economic analysis of hydrogen production from near-shore wind power[J]. Southern Energy Construction, 2025, 12 (3): 33-41 (in Chinese) | |

| [28] | 孙建梅, 郭烜博. 近海海上风电制氢经济性分析[J]. 现代电力, 2025, 42 (3): 523-530. |

| Sun J M, Guo X B. Economic analysis of hydrogen production from near-shore wind power[J]. Modern Electric Power, 2025, 42 (3): 523-530 (in Chinese) | |

| [29] | 黄伟捷, 江岳文. 远海风电输电和制氢经济可行性分析[J]. 中国电力, 2022, 55 (1): 91-100. |

| Huang W J, Jiang Y W. Current status and outlook of hydrogen production and utilization in China[J]. Electric Power, 2022, 55 (1): 91-100 (in Chinese) | |

| [30] | Franco B A, Baptista P, Neto R C, et al. Assessment of offloading pathways for wind-powered offshore hydrogen production: energy and economic analysis[J]. Applied Energy, 2021, 286: 116553 |

| [31] |

徐政, 程斌杰. 不同电压等级直流输电的适用性研究[J]. 电力建设, 2015, 36 (9): 22-29.

doi: 10.3969/j.issn.1000-7229.2015.09.004 |

| Xu Z, Cheng B J. Study on the applicability of DC transmission with different voltage levels[J]. Electric Power Construction, 2015, 36 (9): 22-29 (in Chinese) | |

| [32] | 曾丹, 姚建国, 杨胜春, 等. 柔性直流输电不同电压等级的经济性比较[J]. 电力系统自动化, 2011, 35 (20): 98-102. |

| Zeng D, Yao J G, Yang S C, et al. Economical comparison of different voltage levels of flexible DC transmission[J]. Power System Automation, 2011, 35 (20): 98-102 (in Chinese) | |

| [33] | 黄明煌, 王秀丽, 刘沈全, 等. 分频输电应用于深远海风电并网的技术经济性分析[J]. 电力系统自动化, 2019, 43 (5): 167-174. |

| Huang M H, Wang X L, Liu S Q, et al. Technical and economic analysis of frequency division transmission applied to deep sea wind power grid connection[J]. Power System Automation, 2019, 43 (5): 167-174 (in Chinese) | |

| [34] | 程斌杰, 徐政, 宣耀伟, 等. 海底交直流电缆输电系统经济性比较[J]. 电力建设, 2014, 35 (12): 131-136. |

| Cheng B J, Xu Z, Xuan Y W, et al. Economic comparison of submarine AC/DC cable transmission system[J]. Electric Power Construction, 2014, 35 (12): 131-136 (in Chinese) | |

| [35] | 朱孟喆. 海上风电水解制氢经济性分析和展望[J]. 风能, 2024 (1): 80-83. |

| Zhu M Z. Economic analysis and prospect of hydrolysate hydrogen production from offshore wind power[J]. Wind Energy, 2024 (1): 80-83 (in Chinese) | |

| [36] | International Renewable Energy Agency (IRENA). Hydrogen from renewable power: technology outlook for the energy transition[R]. Abu Dhabi: International Renewable Energy Agency, 2018 |

| [37] | Koj J C, Wulf C, Schreiber A, et al. Site-dependent environmental impacts of industrial hydrogen production by Alkaline water electrolysis[J]. Energies, 2017, 10 (7): 860 |

| [38] | Kuckshinrichs W, Ketelaer T, Koj J C. Economic analysis of improved Alkaline water electrolysis[J]. Frontiers in Energy Research, 2017, 5: 1 |

| [39] | Xu Y, Yang K, Yuan J. Levelized cost of offshore wind power in China[J]. Environmental Science and Pollution Research, 2021, 28 (20): 1-14 |

| [40] | Fan J L, Yu P, Li K, et al. A levelized cost of hydrogen (LCOH) comparison of coal-to-hydrogen with CCS and water electrolysis powered by renewable energy in China[J]. Energy, 2022, 242: 123003 |

| [41] | Man J, Ma T, Yu Y, et al. Levelized costs and potential production of green hydrogen with wind and solar power in different provinces of Mainland China[J]. Journal of Renewable and Sustainable Energy, 2024, 16 (2): 025902 |

| [42] | 王彦哲, 欧训民, 周胜. 基于学习曲线的中国未来制氢成本趋势研究[J]. 气候变化研究进展, 2022, 18 (3): 283-293. |

| Wang Y Z, Ou X M, Zhou S. Study on the future cost trend of hydrogen production in China based on learning curve[J]. Climate Change Research, 2022, 18 (3): 283-293 (in Chinese) | |

| [43] | EVTank联合伊维经济研究院. 中国氢气存储与运输产业发展研究报告(2019)[R]. 北京, 2019. |

| EVTank and Ivey Economic Research Institute. Hydrogen storage and transportation industry development research report in China (2019)[R]. Beijing, 2019 (in Chinese) |

| [1] | 许传博, 王乐凯, 史超凡, 秦光宇, 刘建国, 刘琦, 刘畅. 多情景下我国氢能产业中长期供需结构及碳排放模拟研究[J]. 气候变化研究进展, 2025, 21(2): 221-235. |

| [2] | 陶学宗, 林泽宇, 许登豪. 集装箱港口集疏运重卡电动化的经济性分析[J]. 气候变化研究进展, 2024, 20(3): 351-360. |

| [3] | 陶学宗, 王谦益, 李汉卿. 船舶使用岸电的经济性分析[J]. 气候变化研究进展, 2022, 18(4): 492-502. |

| [4] | 王彦哲, 欧训民, 周胜. 基于学习曲线的中国未来制氢成本趋势研究[J]. 气候变化研究进展, 2022, 18(3): 283-293. |

| [5] | 田惠玲, 朱建华, 李宸宇, 肖文发. 基于自然的解决方案:林业增汇减排路径、潜力与经济性评价[J]. 气候变化研究进展, 2021, 17(2): 195-203. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||